Car Transporters

A recent email from Colin McCardell showing the Green Tiger Car Transporter made me think about the two years I spent developing the Oxford Scania version.

Image of loaded car transporter from Colin McCardell

The real thing loaded - image supplied by Colin McCardell

It was back in 2014 that I decided it would be a good time to add a modern car transporter to the Oxford range. I questioned how I would do this, as the latest transporters carry a lot more cars and the loading decks are angled.

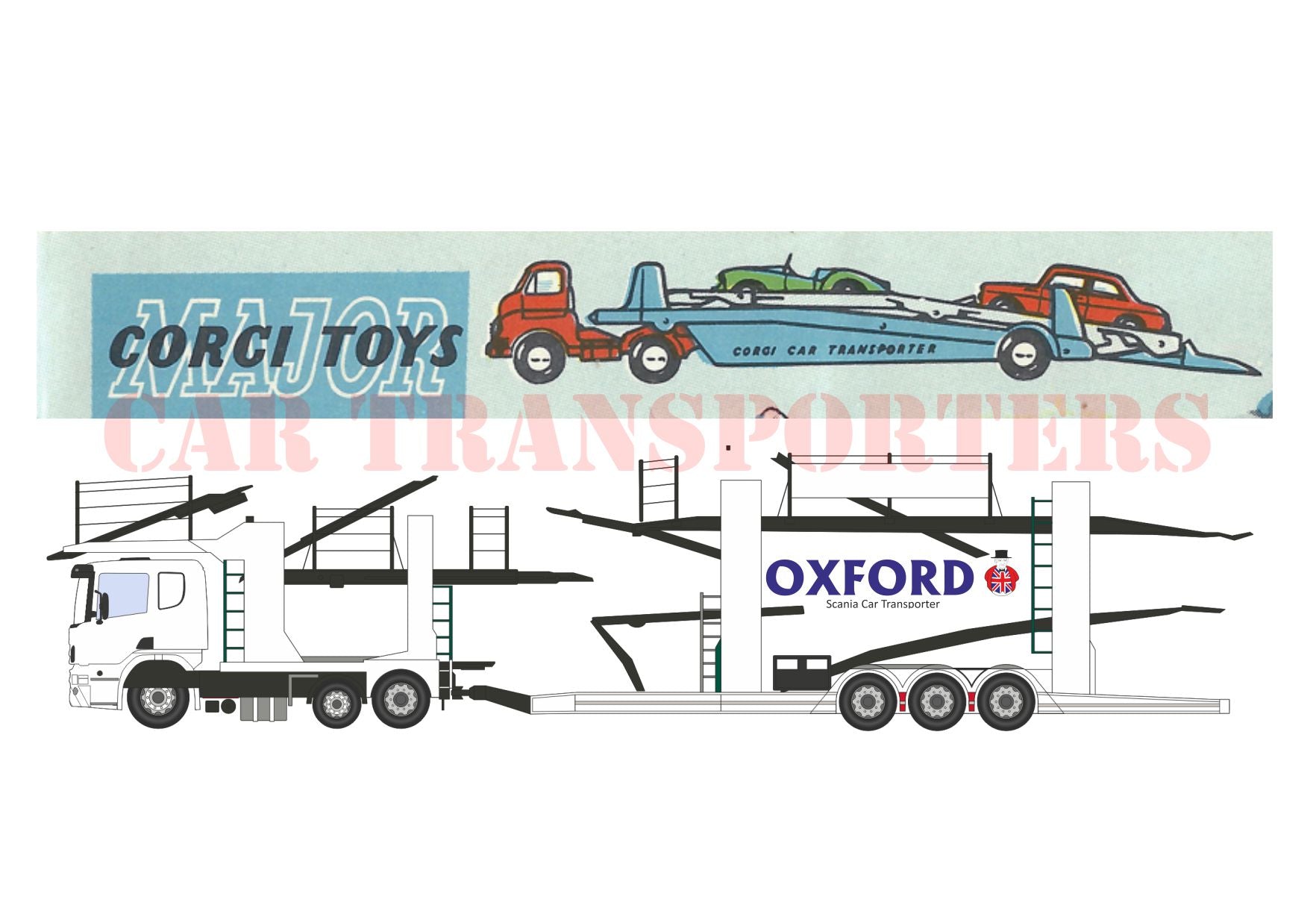

My mind wandered back to the fond memories I have of the Corgi Major Carrimore transporter I played with as a child.

Carrimore Six-Wheelers Ltd and were based at the "Carrimore Works" North Finchley, their origins dated back to Carrosserie Latymer (1915) Limited with the Carrimore 6 wheeler conversions for trucks and steam wagon to increase load capacity. They developed drawbar trailers and supplied the MOD, this advert is from the 1950’s.

Even the above stirs memories as I recall the old adverts with the jingle.

'John Collier, John Collier the window to watch'

I would spend hours as a 9 year old loading different vehicles and angling the hydraulic jacks, I am sure that this early learning led to my interests in engineering.

The first Corgi appeared in the late 1950’s with a Bedford cab.

Corgi Catalogue above from 1958 showing the C1101 Carrimore Transporter and Gift Set 1 with 4 cars. Below the actual Carrimore, and Gift Set 1 in pack.

The transporter was updated in 1963 with a Bedford TK cab and new features.

Below Corgi Catalogue 1963/4 updated Bedford TK Cab, snap action ramp, seats, steering wheel and Glidomatic spring suspension throughout

Plus another Corgi first - cab driving mirrors were added. The boxed Carrimore shown below.

Or if you were lucky enough you could have had Gift Set 28

Then in 1967/8 an updated Ford Cab shown in the Corgi Catalogue below.

The Ford cab was coded C1138, I am sure this was the cab that I owned – but my memory is not so clear on that, as I was more interested in the trailer.

I wished I'd had the Gift Set 48 shown below, that would have been my dream set - but it was far too expensive at over 56 shiilings.

BP placed an order with Corgi in 1986 for 5 million vehicles, these were in the blue boxes and around 100,000 of these were Corgi Junior transporters. They were given away free with petrol purchases and were as you can imagine very popular.

In 1987 we had orders for 15 million vehicles. 12 million Corgi Juniors, 2 million Superhaulers (of which 500,000 were transporters) and 1 million Corgi Classics. There was massive pressure on the factory to meet the deadlines and I was given the task of getting it through the factory over 9 months. Recently I met with some of my old Mettoy/Corgi colleagues, they reminded me of my past 'crimes; as I used to stay on at the factory after 4:00pm when the day shift ended. Unknown to them I would rewrite the schedule for the paint machine, favouring the BP products that I was responsible for.

Corgi had a very large electrostatic machine, painting 20,000 Corgi Juniors each hour. The shift would run from 4-9:30pm, so with a bit of early planning, I could secure my production for days. As Mike Williams headed home thinking his range of products for the standard production would be painted. I would secretly rearrange the programme leaving him with nothing to produce the following day. It cost me quite a lot, as I would buy the shift foreman free beers after the shift finished. His excuses for Mike we would talk over in the pub quit e regularly.

- Mikes casting had been rejected so they painted Taffs.

- The paint for Mikes castings had not arrived, so the only option was to paint Taffs castings..

- The pigmentations for the paints for Mikes castings were wrong.

- etc etc etc

If you wanted to hit your production targets back then 'all was fair in love and war !'

BP Promotion first year 1986

BP Promotion second year 1987

So back to 2014,

How would I produce this new transporter. I researched the real thing spending weeks at CEM Days/FRF in Swansea watching and photographing vehicles coming and going.

These shots below were taken during my research.

That's my Ford top right parked up for the day!

It is skilled job unloading the cars off the ramp.

I like to have every detail for future reference.

At Service Stations when the opportunity arose I would talk to drivers.

This was most useful as you learnt the weight and the width of vehicles.

Some Jaguars out for delivery in this picture above.

At the time I was told that you could only load 6 or 7 Range Rovers and that the Sport version with its wider wheel arches could not be loaded onto some of the earlier transporters.

Fortunately all of these conversations led me to Transporter Engineering Ltd, the manufacturers of the transporters, situated in an old disused airfield, at the edge of the picturesque village of Gosfield, A few calls later I was at the factory watching the real thing being built. I now knew that our model needed to be the latest version - the EVO 6. (Today they make the EVO 8).

As I walked around the factory I saw many images of the EVO units but I had to be careful as some were earlier designs.

There were many pictures on the walls and fortunately I was allowed to photograph some. This backed up what I had been told earlier with 7 Range Rovers loaded.

The picture below shows 11 Fords, I was also learning that different car companies used different cab units that had to be modified.

We would only be tooling one cab, so we would have to choose carefully.

Then my eyes caught sight of what I considered the holy grail,12 vehicles loaded. I had to achieve this capability on our Oxford model

It was now clear to me that the Scania would be the favoured cab. So one last request, could I see a modified Scania, 10 minutes later I was measuring it up.

I returned to my office and agonised over how the cars would be held on the decks, but eventually decided that I had to have securing holes as the cars needed to be displayed in their correct positions without falling off.

When unloaded I wasn’t so happy as these holes were visible, but when loaded the transporter looked perfect and the cars could be secured safely.

I was nervous about this so I also arranged for some scans of the real thing, this shows the point cloud below..

I briefed out some sketches and then set about the design of our 1:76 model. It took ages as I was constantly updating the drawings. I also decided that we needed to experiment with traditional patterns, I wasn't very popular when I asked for them to be made at 1:76 scale.

Typically we would make patterns at between 50 to 100% bigger than the final product to allow the detail to be sharper. By having a 1:1 pattern we could play around with the cars and fixings. After 6 months of squabbling we got there.

This is a bit of CAD which I created from the patterns/scans It is not the smoothest of videos, as my arthritis is playing up in the cold weather.

The front of the leaflet supplied with vehicle - I drew this myself as by now it had become a bit more complicated. You can fit 12 small cars by angling correctly.

Reverse side of leaflet supplied with vehicle

Just to be sure I tested out the Vauxhall Corsa, where 12 vehicles can be loaded by having the ramps correctly angled.

These are the finished vehicles

Sold Out 76SCT001 Oxford Diecast Scania P Car Transporter Eddie Stobart - 1:76 Scale

Half way through the mould making process I realised the Stobart version had banners on the top -I had missed this point. The toolmakers weren't very impressed when I said they needed to be added to the moulds!

More details here for 76SCT002 Oxford Diecast Scania EVO6 Car Transporter Quinns

More details here for 76SCT003 Oxford Diecast Scania Car Transporter Woodside Motorfreight Ltd

More details here for 76SCT005 Oxford Diecast Eddie Stobart Car Transporter - Christina Frances

More detiails here for 76SCT006 Oxford Diecast ECM

More dettails here for 76SCT007 Oxford Diecast Scania Car Transporter Robinsons Autologistics 1:76

These are the Design Cells, which are critical to the manufacturing team and are used extensively through the production process.

So that is a little background to our Scania Transporter. If anyone has any Oxford Diecast transporter pictures to share, either on dioramas or loaded, we would love to add them to our website.

I would also say a big thanks to GWR, as the late running of their train yesterday meant I spent many hours travelling back to Swansea,

All my other work complete I started adding more and more to this blog.

All the best.

Comments

Leave a comment